Mastering environmental and health impacts on the whole line of CO2 capture, transport and geological storage is a critical challenge to ensure the technology is safe and has potential to perpetuate.

What risks in case of leaks ?

The risks related to capturing CO2 are the chemical risks of any industrial process, therefore the factories involved must comply with environmental standards (“ICPE” standards: installations classified for environmental protection). The risks with transportation are linked to the supercritical state of CO2, as its reactions in case of pipeline breakage are still relatively unknown. At the storage stage, the responsibility is to prevent all impact on environment and ensure that the CO2 is not going back up to the surface, whilst limiting any disturbance in the subsoil milieu.

Health impacts

CO2 is neither explosive nor flammable. We breathe this gas every day in the air. It is harmless in little quantity but can have dangerous effects (fainting fit, asphyxia) when its concentration in the air exceeds 5%. If it leaks in an open or flat area, CO2 will disperse quickly, even without any wind. The main danger lies in confined sites or basins type of relief.

Environmental impacts

At submarine storage sites, the impacts of CO2 leaking would hit water pH and the marine environment very near the leak.

In the case of an onshore underground leak, the CO2 could affect local flora (limited impact), the acidity of drinking water, or the integrity of rocks (small probability). The effect of the gas on underground waters is still being studied.

However, time is a positive factor for geological storage: with the natural phenomena of CO2 dissolution and mineralization, the risks related to the migration of the gas decline with the years.

Objective: controlling impacts on the long run

Every stage of a storage project is controlled via specific standard checks – from the conception of the project, through the injection phase, to several decades after the site is closed.

In order to capture CO2 and store it underground, the existing technologies of the oil and gas industries can serve as a model. However, the CO2 must be stored for long periods of time: several centuries – even millennia, and without a risk for the environment. Consequently, the monitoring processes will have to be adapted in terms of length and scale.

Stages of monitoring

The first analyses are carried out during the selection of a storage site: before CO2 is injected, the area that is considered for the experiment is investigated to ensure it meets all safety requirements – especially geological stability (minor seismic hazard) and a waterproof overburden of the rock. Then each site is kept under scrutiny from the exploitation phase until it is shut down, and also in post-exploitation so as to follow the evolution of storage and track potential migration of CO2.

Levels of monitoring

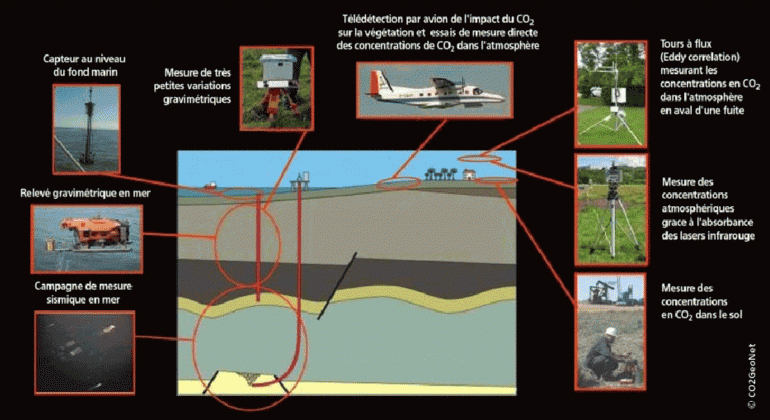

A combination of techniques must be employed to observe the CO2 geological storage and make sure it is safe over time: modeling and on site measures, to predict the gas behavior, identify potential migration roads and anticipate its possible impacts on the population, wildlife and plants nearby.

Besides the evolution of the gas, it is also necessary to control any changes in the properties of the reservoir rock and overburden, CO2 concentrations at the surface, and water quality in the upper Aquifers between the storage place and the surface.

Lastly, an essential part of the monitoring process is to study the effect of extra substances that were injected with the CO2, the potential trace elements moved to the reservoir or cover layers following chemical disruptions, and in certain cases the original gases removed when the CO2 was injected (methane or sulfur hydrogen). These complex issues are regularly or permanently reviewed by measuring systems.

Illustrated examples of monitoring techniques for a CO2 storage site

Site surveillance by modeling

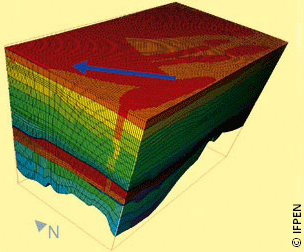

With digital modeling, researchers can foresee the evolution of CO2 on the long view, simulate various scenarios and identify potential CO2 migration risks (via the overburden, the well or a leak).

Models are of two scales: the reservoir or the Sedimentary basin on the whole. Several models that can either be static or dynamic are used:

To shortlist the possible storage sites, static geological models are devised to assess whether a site if fit to receive CO2 or not.

The engineering models of the reservoir are initially used to understand hydrocarbon deposits. They give information on how fluids move about and the interactions between water, gas and oil.

They can be coupled to geomechanical models, updating on the possible deformation or cracking of the reservoir rock and overburden.

Lastly, geomechanical models take into account the chemical interactions between waters in which CO2 was dissolved and minerals.

To stay relevant, these models must by updated with the different measurements taken on site (especially seismic), which helps monitor the geomechanical evolution of the reservoir and map the transfers of CO2 over time.

Légend : Model of hydrodynamics at a regional scale (length 50km, width 36km and height 5km).